Chemical Reaction Furnace for Processing Ultra-thin Glass

Main Use

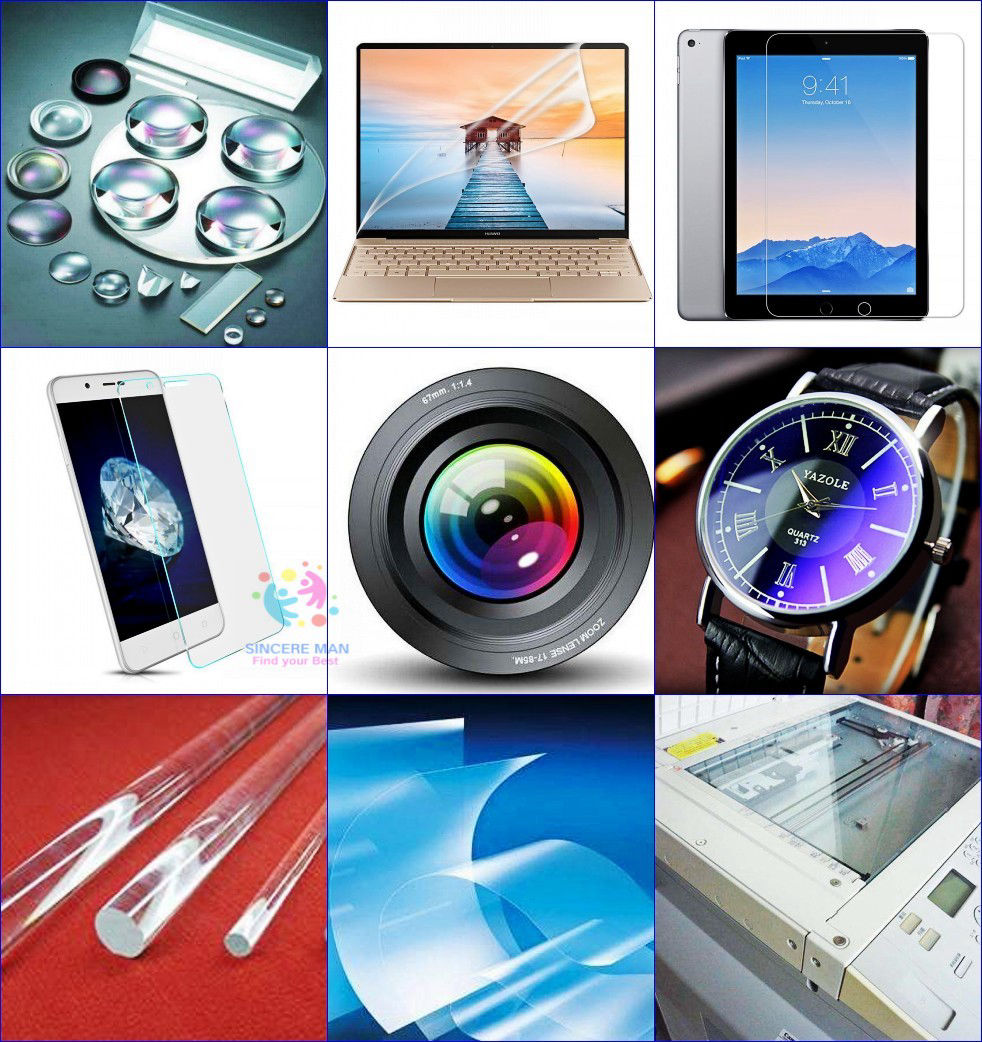

Electronic products glass: touch screen in mobile-phone,computer screen, computer touch conductive glass, ultra-thin TV sets, view-finder glassion glass

Home appliance glass:scanner glass, duplicating machine glass, ultra-thin cupboard glass, washing machine view-finder glass, plasma TV glass

Optical glass: Ultra-photopermeability glass, ultra-toughened glass, ultra-smooth glass, ultra-thin tempering glass, watches glass, precision instrument lens.

Features

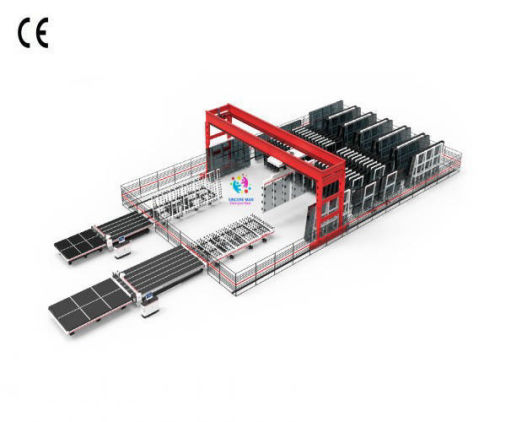

1.Surface strength improvement: Chemical tempering furnace treatment can significantly improve the surface strength of glass, making it more impact resistant and durable.

2.Not changing the transparency of glass: Chemical tempering does not alter the transparency and optical properties of glass, maintaining its original clarity.

3.Improved wear resistance: The treated glass surface is more wear-resistant, able to resist scratches and wear, improving the durability of the product.

Manufacturing curved glass: Chemical tempering furnaces can be used to manufacture curved glass, increasing flexibility in construction and design.

4.Improving corrosion resistance: Chemical treatment can improve the chemical properties of the glass surface, enhance its corrosion resistance, and make it more suitable for harsh environments.

5.Manufacturing high-end products: This technology is often used to produce high-end glass products, such as smartphone screens, tablet screens, etc., to improve product performance.

Improving glass fracture mode: In the event of breakage, chemically tempered glass disperses into small particles, reducing sharp fragments and improving safety.

6.Highly automated: Chemical tempering furnaces are usually equipped with advanced automation systems, making the production process more efficient, controllable, and repeatable.

7.Widely applicable: Chemical tempering technology is suitable for glass of different shapes and sizes, meeting the needs of various fields, including construction, automotive, home and electronics industries.

8.Environmental friendliness: Compared to traditional heat treatment methods, chemical tempering is usually more environmentally friendly because it does not require the use of high-temperature furnaces, thereby reducing energy consumption.