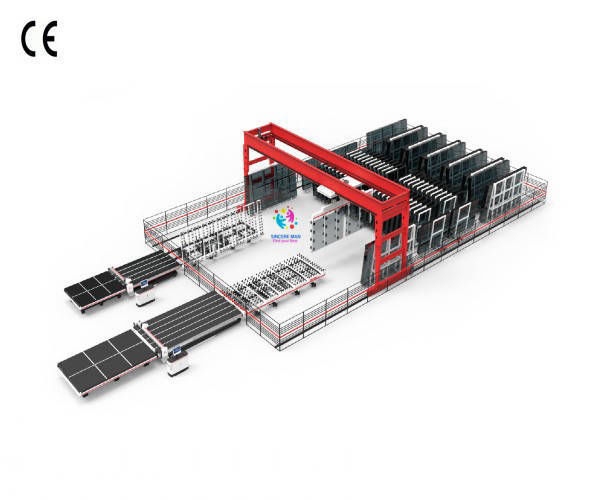

Vertical Insulating Glass Line

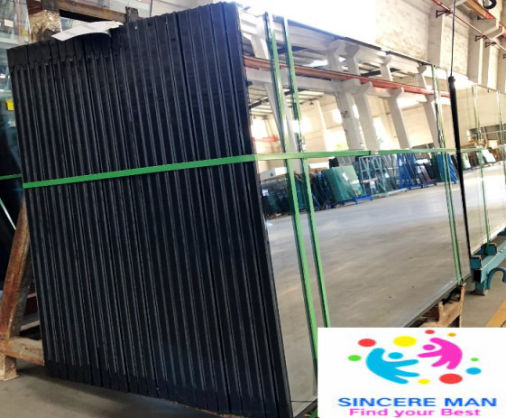

Vertical insulating glass production line is an equipment used for manufacturing insulating glass. Hollow glass is a product that is separated by two or more layers of glass panels through aluminum spacer strips or other spacer materials, forming a certain air layer to improve the thermal insulation, sound insulation, and shock resistance of the glass. The vertical insulating glass production line plays a key role in the manufacturing of insulating glass, with the following purposes and advantages.....……

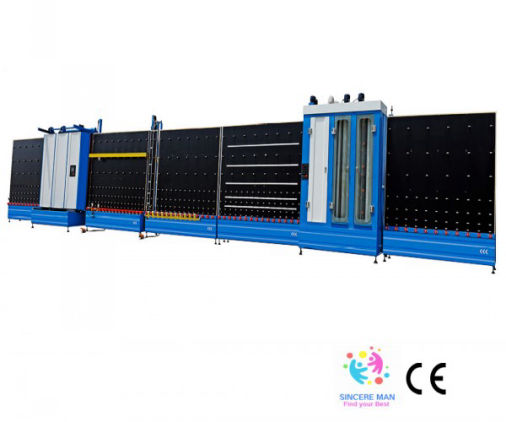

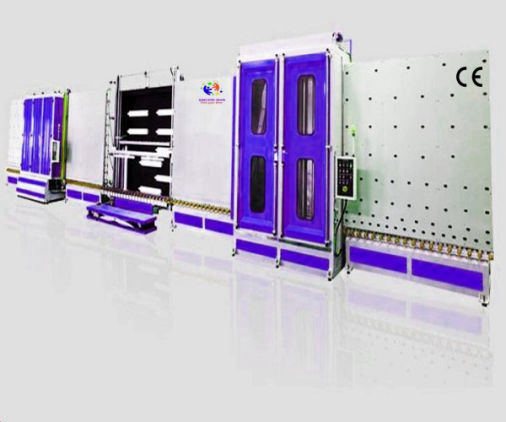

Vertical Automatic Insulated Glass Inflation Production Line

Vertical Automatic Insulated Glass Inflation Production Line mainly consists of loading, high-performance stainless steel cleaning machine, conveyor, lamp inspection aluminum frame positioning, automatic lamination, automatic flat pressing device (internal lamination, plate pressure internal inflation), and conveyor section. This production line can achieve external and internal lamination functions respectively. When inflating, internal lamination is used, and internal lamination can achieve double-layer and three-layer hollow glass inflation (inert gases such as argon). It can be upgraded and customized according to user requirements......……

Super Large Panel Insulated Glass Production Line

Super Large Panel Insulated Glass Production Line mainly consists of loading, high-performance stainless steel cleaning machine, hollow conveying, hollow aluminum frame positioning, automatic lamination, large pass plate pressing, and plate pressing and post conveying. It can process single layer and double layer insulating glass with high efficiency. Upgrade and customize according to user requirements......……